Center Bore:66.1mm

Hardware Seat:60 Degree Conical

Center Bore:66.6mm

Hardware Seat:60 Degree Conical

Center Bore:66.6mm

Hardware Seat:60 Degree Conical

Center Bore:67.1mm

Hardware Seat:60 Degree Conical

Center Bore:66.6mm

Hardware Seat:60 Degree Conical

Center Bore:70.5mm

Hardware Seat:60 Degree Conical

Center Bore:72.56mm

Hardware Seat:60 Degree Conical

Center Bore:71.6mm

Hardware Seat:R14 Ball Seat

Center Bore:PSCL

Hardware Seat:N/A

Center Bore:70.5mm

Hardware Seat:60 Degree Conical

Center Bore:71.6mm

Hardware Seat:60 Degree Conical

Center Bore:66.6mm

Hardware Seat:R13 Ball Seat

Center Bore:67.1mm

Hardware Seat:60 Degree Conical

Center Bore:70.5mm

Hardware Seat:60 Degree Conical

Center Bore:67.1mm

Hardware Seat:60 Degree Conical

Center Bore:71.6mm

Hardware Seat:R14 Ball Seat

Center Bore:71.6mm

Hardware Seat:R14 Ball Seat

Center Bore:66.1mm

Hardware Seat:60 Degree Conical

Center Bore:71.6mm

Hardware Seat:R14 Ball Seat

Center Bore:PSCL

Hardware Seat:N/A

Center Bore:PSCL

Hardware Seat:N/A

Center Bore:70.3mm

Hardware Seat:60 Degree Conical

Center Bore:66.6mm

Hardware Seat:60 Degree Conical

Center Bore:71.6mm

Hardware Seat:R14 Ball Seat

Center Bore:PSCL

Hardware Seat:N/A

Center Bore:71.6mm

Hardware Seat:R14 Ball Seat

Center Bore:PSCL

Hardware Seat:N/A

Center Bore:72.56mm

Hardware Seat:60 Degree Conical

Center Bore:64.1mm

Hardware Seat:60 Degree Conical

Center Bore:70.5mm

Hardware Seat:60 Degree Conical

Center Bore:PSCL

Hardware Seat:N/A

Center Bore:PSCL

Hardware Seat:N/A

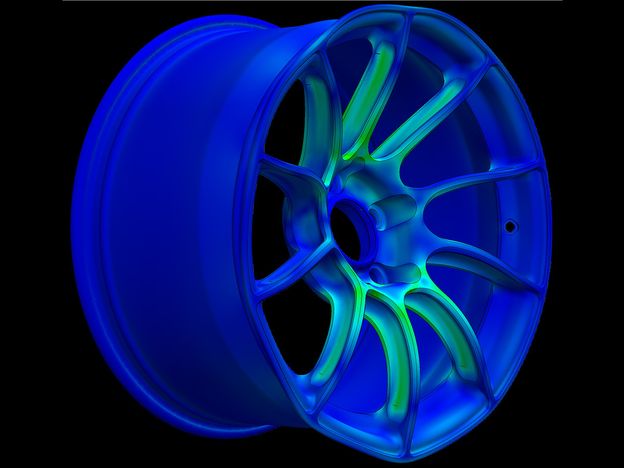

The new VS-5RS, part of our Sprintâ„¢ Line of forged wheels, features reduced weight and greater stiffness to improve lap times.

- 10K Ton Forged 6061-T6 Aluminum

- I-Beam Spokes for Reduced Weight

- Stronger Sprintâ„¢ Spec Inner Lip

- Massive Brake Clearance

- Paintless Knurled Beads

- Unmatched Replacement Program

- Lifetime Structural Warranty

- Independently Tested and Certified

As part of our Forged Sprintâ„¢ Line, the VS-5RS was built to be extremely light while still offering a meaningful strength increase over our flow formed wheels. For those looking to shed as much weight as possible to improve lap times.

10K Tons of Pressure

Our new forgings weigh as much as 120 pounds before machining. To form such a thick blank we require special equipment capable of 10,000 metric tons of pressure. This extreme pressure increases the strength of the aluminum by eliminating porosity and improving the grain structure.

True Motorsport Blanks

Many companies use 3rd-party blanks intended for non-motorsport wheels which can severely limit sizes, concavity, spoke design, and critical brake clearance. We designed our very own blank profiles from scratch to give us total control over the final product.

I-Beam Spokes

One of the most noticeable features of the VS-5RS is its use of side-milling on both sides of each spoke, creating an I-beam effect. Any excess material that doesn’t add strength is carved out using a precision CNC ball cutter. Side-milling is often deemed cost-prohibitive by others, but for true performance without compromise we believe it's essential.

A Stronger Lightweight Wheel

Our forged Sprintâ„¢ wheels are lightweight without the strength compromises found on typical lightweight wheels. First, we carved out as much material as possible, then we purposefully added one pound back to reinforce critical areas, creating a stronger inner lip and a higher load rating. ² What’s the point of a lightweight wheel if it’s fragile?

Load Ratings (lbs)

JWL Load Standard - 1521

Typical Forged Wheels - 1521

APEX Flow Formed - 1550

APEX Forged Sprintâ„¢ Line - 1600

Weight Optimized

We conducted extensive Finite Element Analysis (FEA) to reinforce high-stress areas and to remove material where it didn’t improve strength. The result is a wheel that is exceptionally light without the strength compromises found on typical lightweight wheels.

Greater Stiffness

The VS-5RS is not just another style to choose from. We used Finite Element Analysis of bending loads to optimize spoke geometry for greater stiffness without increasing weight. In fact, the VS-5RS is nearly identical in weight to our popular VS-5RS yet almost 10% stiffer, and 25% stiffer than our first generation of forged wheels.

Independently Tested

We don't rely solely on computer simulations or unverifiable in-house testing. We believe independent testing is critical to protect consumers in this unregulated industry. We chose STL, an independent lab in Ohio, to test our Sprintâ„¢ wheels far above JWL standards, including increases in testing duration, impact drop height, and total load.

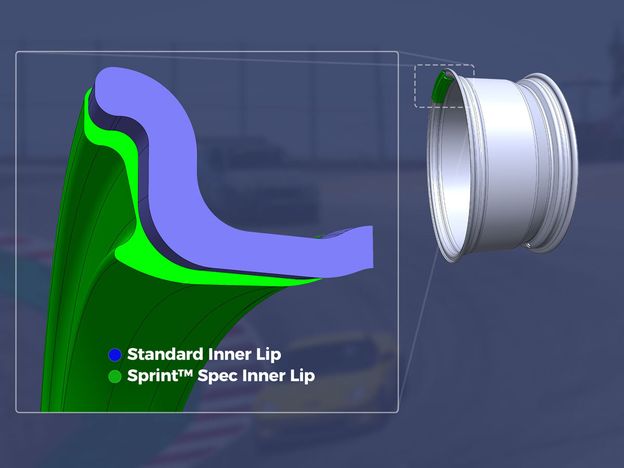

Tougher Inner Lip

Introducing the Sprintâ„¢ spec inner lip, with a unique channel profile that makes it even stronger than our previous designs. So even though our Sprintâ„¢ wheels are pounds lighter than comparable flow formed wheels, the inner lip is stronger.

32% more reinforcement than our flow formed wheels!

Big Brake Clearance

From day one, APEX has been on a mission to build wheels that clear big brakes. Our new forged wheels are the product of everything we’ve developed over the past 10+ years, including an innovative high-clearance barrel design and vehicle-specific spoke profiles.

Deeper Concavity

Our new forgings were redesigned to create extra deep, concave spoke profiles. Their new shape allows us to make any profile, from flat to deep and everything in between. Each one is optimized for a specific application using 3D laser scans of factory and aftermarket brake kits.

Paintless Knurled Bead

Whether it's a day at the track or months of street driving, repeated hard braking and acceleration can make a tire slip along the bead seat and go out of balance, causing vibration. Knurled beads help, but are less effective when painted over. Our forged line features unpainted knurled beads that stay sharp and maximize grip.

Built for Impact Sockets

Track wheels need track tools. Don’t settle for wheels that require undersized tuner lugs or thin walled sockets. All APEX wheels accommodate over-sized race lugs and impact sockets to make swapping wheels lightning fast. 32mm Socket diameter clearance.